Hot wire CNC foam cutters

If you are looking for a hot wire CNC foam cutter machine for your company’s production facilities, it is worth checking first what functions they can offer and what machines you can choose from. The most popular are hot wire CNC. Foam cutters and string plotters are also popular. Below we will discuss these machines and their features.

Hot wire CNC foam cutters

Depending on how big your production needs are, different models of manual tools and hot wire CNC foam cutter are available on the market. The latter ensure extraordinary precision and efficiency of the production process. Such machines for cutting polystyrene, polystyrene, XPS polystyrene, EPS will be useful wherever it is necessary to cut any shape in such material.

In the offer of suppliers on the market, you can find hot wire CNC foam cutters, which are small devices for cutting signs for companies, as well as huge industrial machines or entire production lines. Such hot wire CNC foam cutters are also great for construction and architecture. Equipped with electric, spring or pneumatic tension, they efficiently and quickly allow you to carry out the cutting process.

Modern hot wire CNC foam cutters are equipped with many improvements such as:

- independent arm movement

- several cutting wires at the same time

- optional additional rotary tables and lathes

- shaped wires

- remote controls with displays

How to choose the right hot wire cnc foam cutter for polystyrene

Certainly, with the help of the supplier and manufacturer of such plotters, you can choose the right machines with the right accessories for yourself. These are quite unusual machines, so in the case of non-standard and individual needs, manufacturers are usually able to adjust the size, parameters and functions of the machine to specific needs.

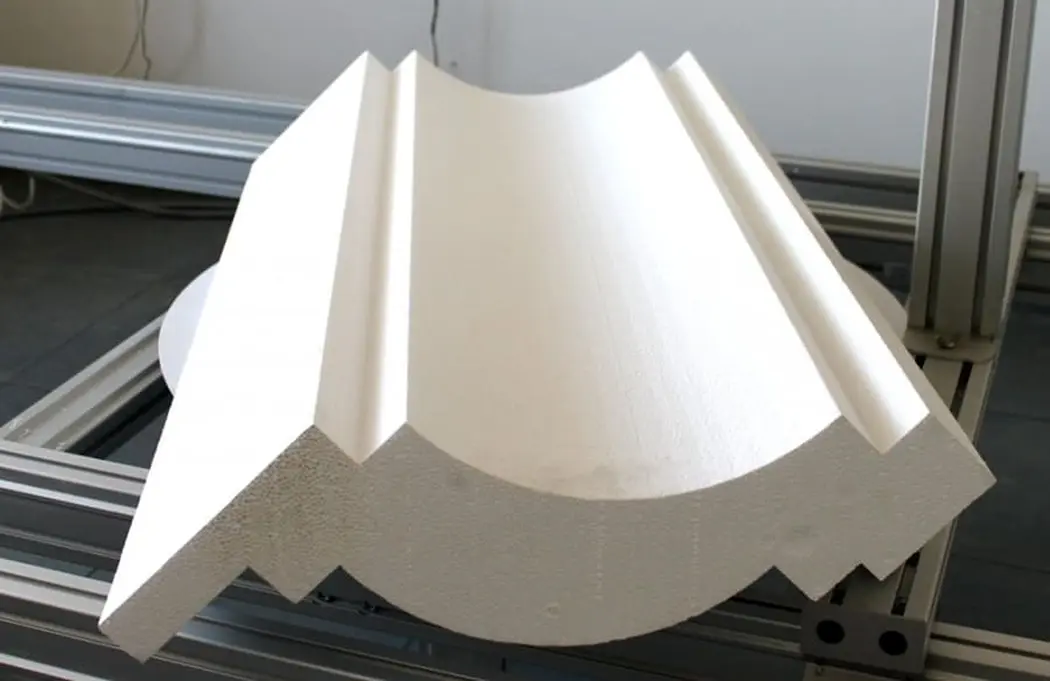

The hot wire cnc foam cutter can cut virtually any shape from polystyrene, XPS polystyrene, EPS and other materials. Using the turntable, you can cut 3D models or flat 2D designs. The precise rotary mechanism allows for symmetrical cutting of complex shapes.

Hot wire CNC for styrodor

Lathes installed in hot wire CNC foam cutters for styrodor and polystyrene allow cutting out various types of rotating elements. Thanks to this, we can obtain curly and rotating shapes. If you want to make 3D shapes, architectural elements and details that require complex operations, then the function of the lathe and shaped wire will certainly be needed and very useful.

The hot wire cnc foam cutter is used in the cutting and production of many different elements. Wall insulation and architectural elements will be made saving a lot of time and with the highest quality. It will also be useful for film decorations, fairs, shop windows, where in a short time and without spending a lot of money, you can create virtually any element of the scenography.

CNC hot wire foam cutters are able to cut any shape

It is worth mentioning that modern hot wire CNC foam cutters are equipped with CNC computer numerical control. Thanks to this, any 3D objects made of extruded and expanded polystyrene (EPS and XPS) can be designed and cut using a PC with the highest repeatability and precision.

Cutting is done by means of a hot wire CNC that moves in the vertical and horizontal axis thanks to the use of stepper motors controlled by an electronic controller connected to a computer and controlled by a unique software.

The advantage of using CNC foam cutters is the fact that the files that are then used to cut out the shape can be prepared in the most popular graphic programs such as Adobe Illustrator, AutoCAD, Corel.

Using various strings and resistance wires, hot wire CNC foam cutters can perform automatic cutting or manual cutting using a wired remote control (without drawing and program preparation). Thanks to such a remote control, you can also monitor the current processing parameters (rotation speed, processing speed) on an ongoing basis and, if necessary, make their instant correction during the plotter cutting process.

Autor: Materiał partnera